Automatic glass bottle hot filling machine for apple, mango, orange, and grape pulp juices. Ensures precise, hygienic bottling, ideal for high-quality juice production plants with efficient hot-fill operations.

This automatic hot juice filling machine with high quality and best price is 3 in 1 monoblock for juice hot filling, have 3 functions, washing, filling and capping. Hot Filling Monobloc composes of liquid feeding pipes, liquid distributor, 2 filling system(juice and pulp), CIP dummy cup, re-circulation system with precise filling temperature control and level control, all liquid contacting parts are made of 316L or foodstuff rubber and plastic. Links has been manufacturer and devoted sales of juice filling line for more than 15 years, kindly trust us and choose us.

The machine adopt high technology from Italy, can be suitable for juice, vitamin drinks, and other flavor juice, with easy operation control system.

| MODEL | CAPACITY (5000ML)(PER HOUR) |

| RXGF14-12-5 | 5,000BPH |

| RXGF16-16-5 | 7,000BPH |

| RXGF24-24-8 | 10,000-12,000BPH |

| RXGF32-32-8 | 15,000BPH-16,000BPH |

| RXGF40-40-10 | 18,000BPH |

| RXGF50-50-12 | 21,000BPH |

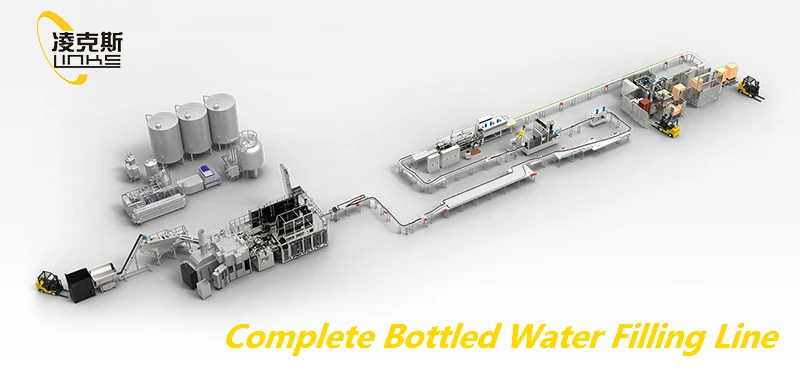

We also provide the Complete Automatic Water Bottling Plant

It Includes 5 main parts:

1/ Plastic bottle blow molding machine

2/ Water cleaning system

3/ Water washing, filling, capping machine.

4/Conveyor system, labeling machine, dating machine, film wrapping machine

|

Project Name: Complete Water Bottling packaging Plant

|

|||

|

Bottle Information

|

|||

|

Suitable Bottle Material

|

PET/Plastic/Glass

|

||

|

Suitable Bottle Shape

|

Round & Square/Others

|

||

|

Suitable Bottle Volume

|

150ml to 2000ml

|

||

|

Water Source Information

|

|||

|

Suitable Raw Water Resource

|

City Water

|

Lake&

River,

|

Mountain Water&Underground Water,

|

|

Filling type

|

|||

|

High Temperature Filling

|

Normal Temperature

|

||

|

Packing Information

|

|||

|

Producing Speed Selection

(Based on 500ml) |

2000BPH, 5000BPH, 7000BPH, 10,,000BPH; 12,000BPH,

15,000BPH,15,000BPH, 18,000BPH……36,000BPH |

||

|

Machines Material

|

All material (which touch water) adopts SUS304&SUS316

|

||

|

Labels Selection

|

PVC & OPP & Adhesive Label …

|

||

|

Date Printer Type Selection

|

Ink & Laser

|

||

|

Packing Type Selection

|

Carton

|

Film Wrap

|

Carton Tray Film Wrap

|

|

Packing Quantity

|

2*3; 3*4; 4*5; 4*4; 4*6; 5*6; 6*8……

|

||

|

Warranty

|

12 Months After Installation

|

||

|

Customer’s Factory Information

|

|||

|

Room Temperature

|

10-40 degree

|

||

|

Room Humidity:

|

No Dew

|

||

|

Voltage Supplier

|

380V, 220V, Special voltage please inform

|

||

The complete line main description:

1/ The plant can produce different volume bottles, from 150ml to 2000ml bottles, round and square bottles, plastic and glass bottles. It is very easy to change the different bottle molds.

2/ The plant is highly automatic, you can operate on the touch screen to adjust the machine speed and working.

3/ We have different speed plants, commonly, 2000BPH, 5000BPH, 7000BPH, 10,000BPH, 12,000BPH, 15000BPH,18000BPH..ect 36000BPH.

4/ The material is stainless steel 304, food grade much clean and safe.

5/ We provide the engineers for customer installation, training in customer's factory.

It can be used in various commercial fluids, including drinking water, carbonated beverages, juice, tea and alcohols.

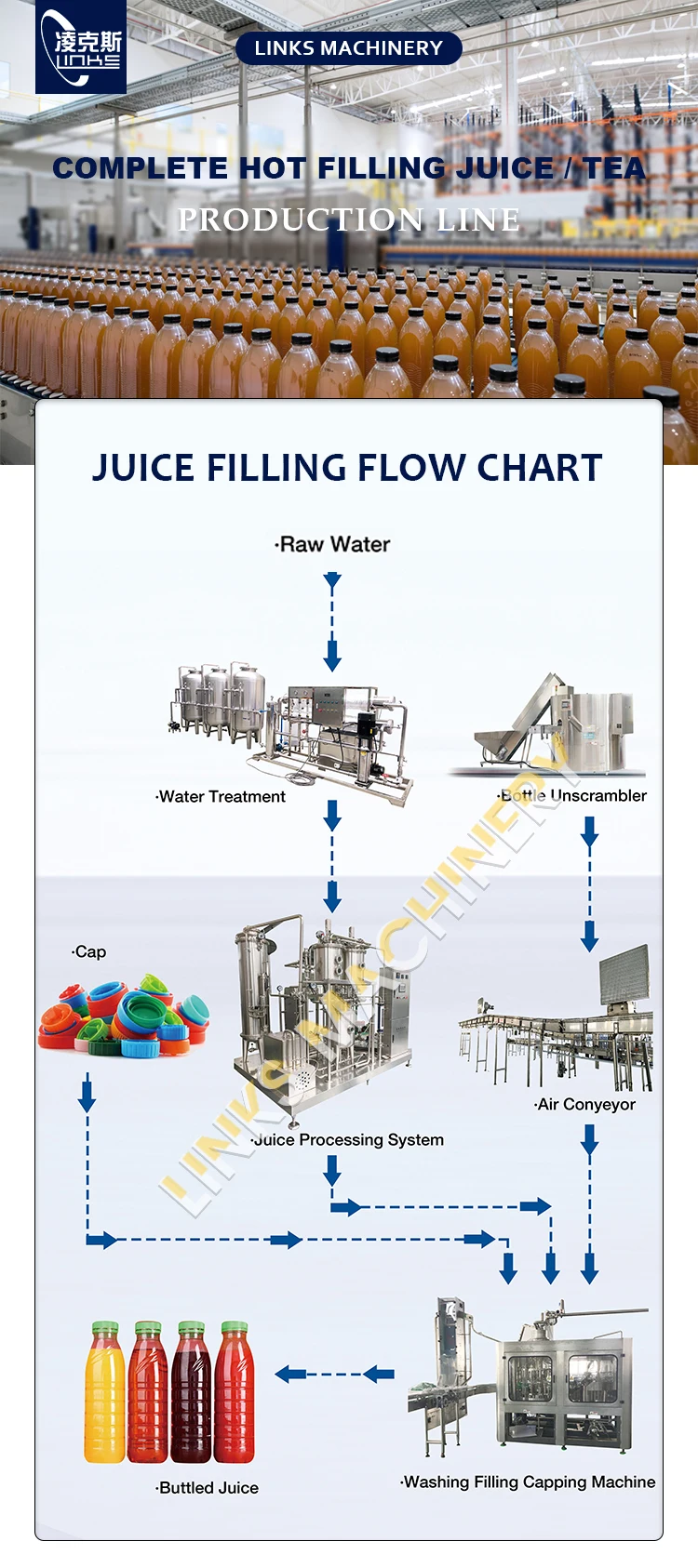

(1)Raw water→ Raw water tank→Raw water pump

(2)Quartz sand filter→ Activated carbon filter→Sodium-ion exchanger→Ultra filter

(3)High pressure pump Reverse Osmosis

(4)Qzone sterilizer→ Pure water tank.

Links machine is a professional liquid and beverage packaging machine supplier in china. Insist on innovation, provide top-grade products and excellent service is our guarantee to win the market. Our packaging equipment covers the field of beverages, alcohol, dairy, condiments and personal care products. According to the customer's packaging design and factory layout, we will provide you most professional packaging solutions, including bottle design, beverage formula, water treatment, pre-treatment, blowing system, filling system and packaging system. In the future, we will keep up with the global beverage packaging industry trends and provides newset filling packaging solutions. To build the ultimate beverage factory with the newest industrial intelligence technology.

Links machine is a professional liquid and beverage packaging machine supplier in china. Insist on innovation, provide top-grade products and excellent service is our guarantee to win the market. Our packaging equipment covers the field of beverages, alcohol, dairy, condiments and personal care products. According to the customer's packaging design and factory layout, we will provide you most professional packaging solutions, including bottle design, beverage formula, water treatment, pre-treatment, blowing system, filling system and packaging system. In the future, we will keep up with the global beverage packaging industry trends and provides newset filling packaging solutions. To build the ultimate beverage factory with the newest industrial intelligence technology.

Sea worthy packing(Wooden case package).

1/Installation and Training

We have professional engineer for oversea installaion and training, they can speak English, and have much experience oversea work.The engineers will install the machine according to the prior layout and make it in the best condition. They will train your technicians how tomaintain the machine and treat different failures.

2/About the bottle drawing, workshop layout, and labels design

We can help customers design their own bottle shape, workshop layout and label drawings, these jobs are free charge.(Workshop need customer to provide the size of factory)

3/Quality guarantee and after-sales service

Our company provides comprehensive after-sales service and technical support,We promise that our goods are all new and did detailed test before delivery.Our machines has a one-year warranty, and once problems arise, we will supply the fastest and most professional solution.

1) Can your factory provide the whole plant from A to Z?

A: Yes, we can provide the complete plant, from bottling making plant, water purification plant, to filling packing plant.

2) Are all machinery your factory made?

A: Our factory make the water purification and filling packing plants. We do not make the bottle making machinery,

we have good quality bottle making machinery partner, and we provide to customer same long warranty time and good after service.

3) How can I know the machinery quality before I order?

A: Frist, we will invite you visiting our factory to check the machines quality, and show the machines running for you in our factory.

4)What certificates you can provide?

A: Our factory provide the CE, SGS, ISO, and accroding to some countries, we also can provide the Pvoc, Coc, Soncap...ect

5)Can your factory make the bottle drawing, workshop layout, and labels for us?

A: We can help customers design their own bottle shape, workshop layout and label drawings, these jobs are free charge.

(Workshop need customer to provide the size of factory)

6)Installation and Training Time

A: We have professional engineer for oversea installaion and training, they can speak English, and have much experience oversea work

Copyright © ZHANGJIAGANG LINKS MACHINE CO LTD - Privacy policy