Fully automatic carbonated soft drink filling machine for aluminium cans. Ideal for CSD, soda water, and cola, delivering precise, high-speed, and hygienic canning for efficient beverage production lines.

|

WHAT IS THE DETAILS OF OUR CARBONATED DRINKS FILLER |

|

|

Filling Liquid |

COLA DRINKS, SODA, FANTA, SPRITE |

|

Filling Container T ype |

PET Bottle; Max Diameter 96, Max Height 310mm |

|

Filling Type |

Isobaric Filling |

|

Cap |

Plastic Screw Cap, Sport Cap, Crown Cap...Ect |

|

Filling Temperature |

0-4 ℃ |

|

Label Material |

PVC Sleeve Shrink Label ; Adhesive Label; OPP Label |

|

Wrap Film Material |

PE / PET |

|

Conveyor Mode l |

E mpty Bottle:Air Conveyor Full Bottle:Conveyor Belt |

|

Factory Condition |

Temperature:10~40℃ Humidity:no dew(≤95%) |

|

Resource Voltage |

According Customer ' s Factory Voltage Design. |

|

Efficiency |

> 95 % |

Electric Components Brands Supplier

|

Main composition |

Description Supplier |

|

PLC |

Mitsubishi (Japan) , Siemens (Germany) |

|

Touch screen |

Weinview(Taiwan) |

|

Frequency converter |

Mitsubishi (Japan) , Siemens (Germany) |

|

Air switch |

Schneider (France) |

|

Breaker |

Siemens (Germany) |

|

Contactor |

Siemens (Germany) |

|

Photoelectric switch |

Omron (Japan) |

Our Other Models Informaiton:

|

Model |

DXGF40-40-12 |

DXGF14/12/5 |

DXGF16/16/5 |

DXGF24/24/8(6) |

DXGF32/32/8 |

|

Washing h ands |

40 |

14 |

16 |

24 |

32 |

|

Filling valves |

40 |

12 |

16 |

24 |

32 |

|

Capping h ands |

12 |

5 |

5 |

6 |

8 |

|

Suitable PET/Glass Bottles(150ml to 2000ml) |

|||||

|

Capacity(Speed) Base on 500ml |

15000BPH |

3000BPH |

5000BPH |

7000BPH |

11000BPH |

Automatic 3 IN 1 Carbonated Drinks Rinsing, Filling, Capping Machine

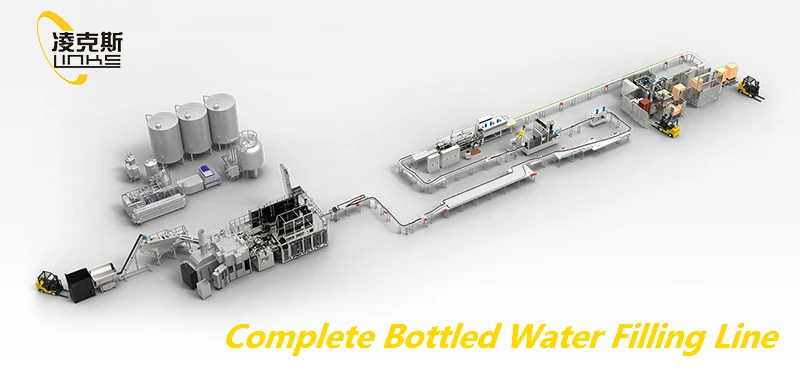

We also provide the Complete Automatic Water Bottling Plant

It Includes 5 main parts:

1/ Plastic bottle blow molding machine

2/ Water cleaning system

3/ Water washing, filling, capping machine.

4/Conveyor system, labeling machine, dating machine, film wrapping machine

The complete line main description:

1/ The plant can produce different volume bottles, from 150ml to 2000ml bottles, round and square bottles, plastic and glass bottles. It is very easy to change the different bottle molds.

2/ The plant is highly automatic, you can operate on the touch screen to adjust the machine speed and working.

3/ We have different speed plants, commonly, 2000BPH, 5000BPH, 7000BPH, 10,000BPH, 12,000BPH, 15000BPH,18000BPH..ect 36000BPH.

4/ The material is stainless steel 304, food grade much clean and safe.

5/ We provide the engineers for customer installation, training in customer's factory.

It can be used in various commercial fluids, including drinking water, carbonated beverages, juice, tea and alcohols.

(1)Raw water→ Raw water tank→Raw water pump

(2)Quartz sand filter→ Activated carbon filter→Sodium-ion exchanger→Ultra filter

(3)High pressure pump Reverse Osmosis

(4)Qzone sterilizer→ Pure water tank.

Zhangjiagang LinksMachinery Co., LTD. is located inZhangjiagang City, JiangsuProvince.It has international standard workshop more than 8000 square meters. It is one of the professional beverage packaging machinery manufacturers with collecting research, developmentand manufacturing. It is China's best beverage machinery equipment suppliers. As liquid packaging industry enterprise, the drink service network is all over the world more than 50 countries and regions, products are widely used in drinks, flavor, cosmetic, beer, milk, and pharmaceutical industries. Since company has begun, focused onthe professional technology --- beverage packaging machinery, to forge leading beverage packaging machinery, upstream and downstream related both beverage packaging equipment research and development. Always adhere to technological innovation to drive the company development.It has been applied for patents, has formed a unique market with competitive advantage. In order to make our equipment performance betterand more stable of operation, our company cooperateswith domestic professional institutes, colleges and universities to carry out the combination of the filling machine andoptimized the related equipment design.

Zhangjiagang LinksMachinery Co., LTD. is located inZhangjiagang City, JiangsuProvince.It has international standard workshop more than 8000 square meters. It is one of the professional beverage packaging machinery manufacturers with collecting research, developmentand manufacturing. It is China's best beverage machinery equipment suppliers. As liquid packaging industry enterprise, the drink service network is all over the world more than 50 countries and regions, products are widely used in drinks, flavor, cosmetic, beer, milk, and pharmaceutical industries. Since company has begun, focused onthe professional technology --- beverage packaging machinery, to forge leading beverage packaging machinery, upstream and downstream related both beverage packaging equipment research and development. Always adhere to technological innovation to drive the company development.It has been applied for patents, has formed a unique market with competitive advantage. In order to make our equipment performance betterand more stable of operation, our company cooperateswith domestic professional institutes, colleges and universities to carry out the combination of the filling machine andoptimized the related equipment design.

Sea worthy packing(Wooden case package).

1/Installation and Training

We have professional engineer for oversea installaion and training, they can speak English, and have much experience oversea work.The engineers will install the machine according to the prior layout and make it in the best condition. They will train your technicians how tomaintain the machine and treat different failures.

2/About the bottle drawing, workshop layout, and labels design

We can help customers design their own bottle shape, workshop layout and label drawings, these jobs are free charge.(Workshop need customer to provide the size of factory)

3/Quality guarantee and after-sales service

Our company provides comprehensive after-sales service and technical support,We promise that our goods are all new and did detailed test before delivery.Our machines has a one-year warranty, and once problems arise, we will supply the fastest and most professional solution.

Copyright © ZHANGJIAGANG LINKS MACHINE CO LTD - Privacy policy