Tanzania-18000BPH Water Filling Line & 5Gallon Filling Line

One morning in January 2024, I had just dozed off in the hospital's accompanying chair when my phone vibrated. It was Amar's WhatsApp message: "We've arrived at Shanghai Pudong Airport." The screen illuminated the wrinkled face of my son in the incubator next to me—he had just emerged from the delivery room at 3 a.m., eyes closed, fists clenched, like a newly hatched bird. I quickly replied, "I'll be right there," touched his tiny feet, quietly greeted the nurse, wrapped my coat tightly around me, and rushed to the airport.

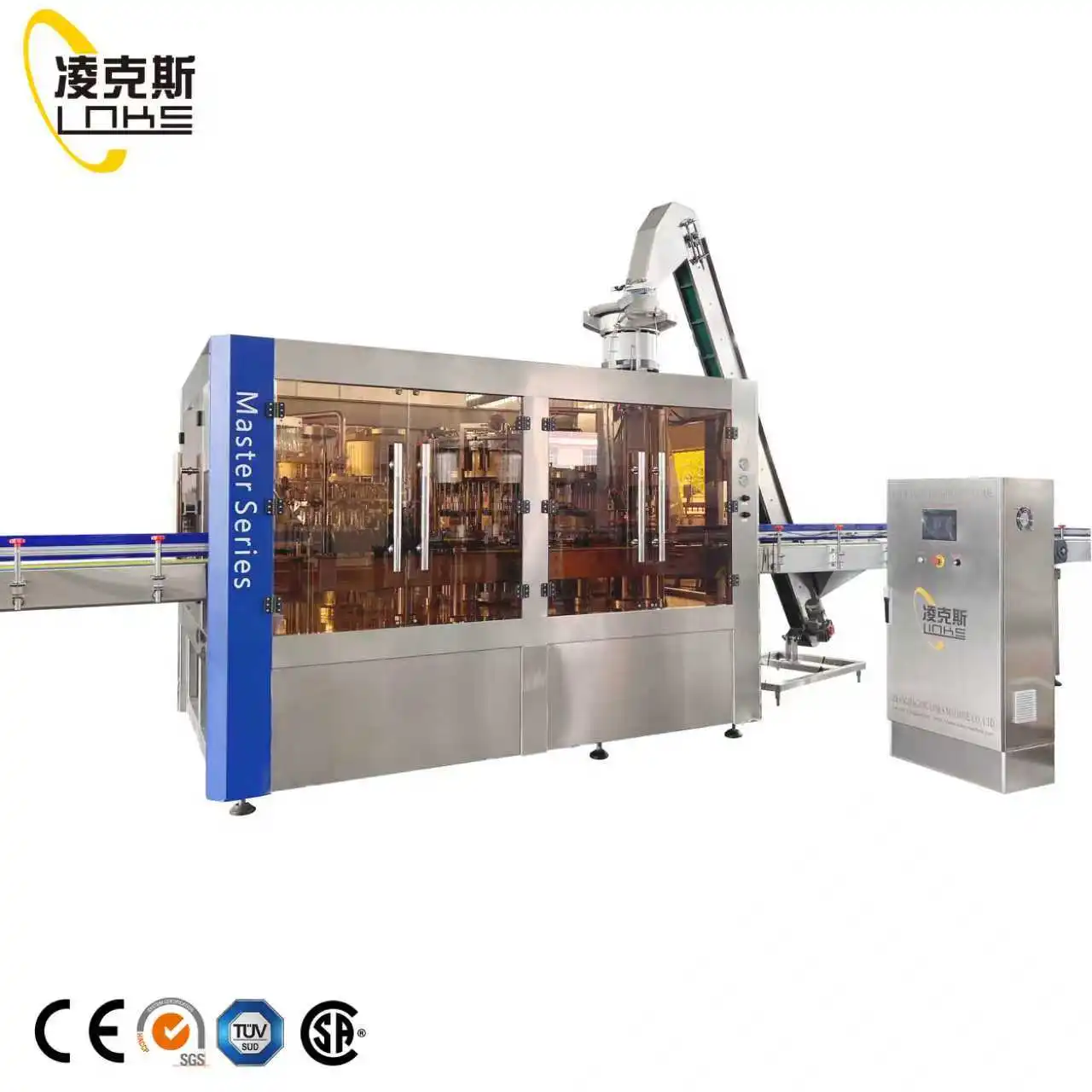

When I picked up Amar and his assistant, Muktar, he was clutching an old folder. He flipped through it as soon as we got in the car. Inside were blurry photos of machines, their iron frames stained with rust. Amar sighed and pointed at me. "We bought a production line two years ago, supposedly capable of running 6,000 bottles. But bottles get stuck every other day, and they're just piled up in the factory as scrap metal." His brow furrowed as he spoke, and my heart sank. Over the past six months, they've been discussing the "failure rate of the blow molding machine" and "compatibility of the film wrapping machine" over and over again on WhatsApp for over twenty times, each time refraining from the question of "fear of falling into a trap again." Seeing him staring out the window, I realized just how tightly they were holding onto that 18,000-bottle order.

They didn't bring it directly to our factory, but instead went to the home of Lao Wang, the blow molding machine supplier. Lao Wang was debugging a prototype in the workshop. Upon seeing us, he immediately opened the hopper lid and pointed to the screw inside, smiling. "I know your Tanzanian PET material sometimes contains small impurities. This screw is 2mm thicker than standard, so even if it rubs against impurities, it won't get stuck. The one we installed for a Kenyan customer last year has been running flawlessly for a year." Amar squatted down and rubbed the coating on the screw with his fingers, saying nothing. Muktar, on the other hand, took out a pen and wrote on the back of a folder: "Thickened screw to prevent impurities."

Later, when I went to see the film wrapping machine, I specifically asked the technician to stop the machine. I pointed to the adjustment lever on the eye mask holder and said, "You sometimes change bottles of different sizes. You don't need to tighten the screws on this adjustment lever; you just turn it to adjust the height. An operator can get the hang of it after practicing twice, so they don't have to wait for a technician." The technician demonstrated it on the spot, switching from a 330ml bottle to a 500ml bottle in just two minutes. Amar finally spoke, "The last time we used that film wrapping machine, it took two hours to adjust each bottle shape, and it still didn't wrap tightly." His tone was less tense.

At lunch in the factory cafeteria, my phone rang. It was a video from my wife. Our son had woken up, staring at the camera with his bright eyes. I held up my phone to show them. Amar leaned over and his eyes lit up. "Just like when my youngest son was born!" He pulled out his own phone and pulled out a photo of a little boy in a red jacket. "That's my second child. He calls me 'Dad' now." Muktar laughed beside him, "Amar always says that once the water plant is up and running, we'll buy our children a house with a yard in the city."

When we returned to our factory that afternoon to review the overall plan, Amar wasn't poring over the datasheets like he had that morning. Instead, he asked about after-sales service. "If there's a problem with the machine, how quickly can you send someone over?" I pointed to the after-sales service form on the wall. "We have a resident technician in Cameroon. It's only a four-hour flight to Tanzania. As long as... It's not a major issue, so it can arrive the same day. We'll also ship an extra set of spare parts for these auxiliary machines with the machines, so you can replace any minor issues yourself.

As night fell, Amar suddenly slammed the table and said, "You're the one." Muktar was stunned, but then he smiled and explained, "They showed us the blow molding machine workshop, the film wrapping machine commissioning, and even opened up the labeling machine parts warehouse for us to see. The last company only dared to display prototypes in the showroom." As he picked up his pen to sign the contract, he paused and looked up at me. "You're here to help us right after your child was born. We trust you."

After signing the contract and rushing to the hospital, I texted my wife, "It's done." She replied with a photo of our son yawning, captioned, "Earning milk powder money for my son." The wind blew in through the car window, bringing a chill, but my heart was warmed. On one side was the soft embrace of a newborn child, gently grasping my heart; on the other, the trust, conveyed across thousands of miles, firmly established. Although I was extremely busy this January, I felt more at ease than ever before.